Blending 3D Printing Skills with Projects at Moorpark High School

At PrintLab, we love seeing classrooms where skills-based learning and creative projects work hand in hand. In today’s guest blog, Chris Guthrie, a Product Innovation and Design teacher at Moorpark High School in California, shares how his students learn new CAD and 3D printing skills through short PrintLab lessons and then apply them immediately in meaningful design projects. This blended approach helps students develop confidence, creativity and real-world problem solving.

8th December 2025 • Case Studies

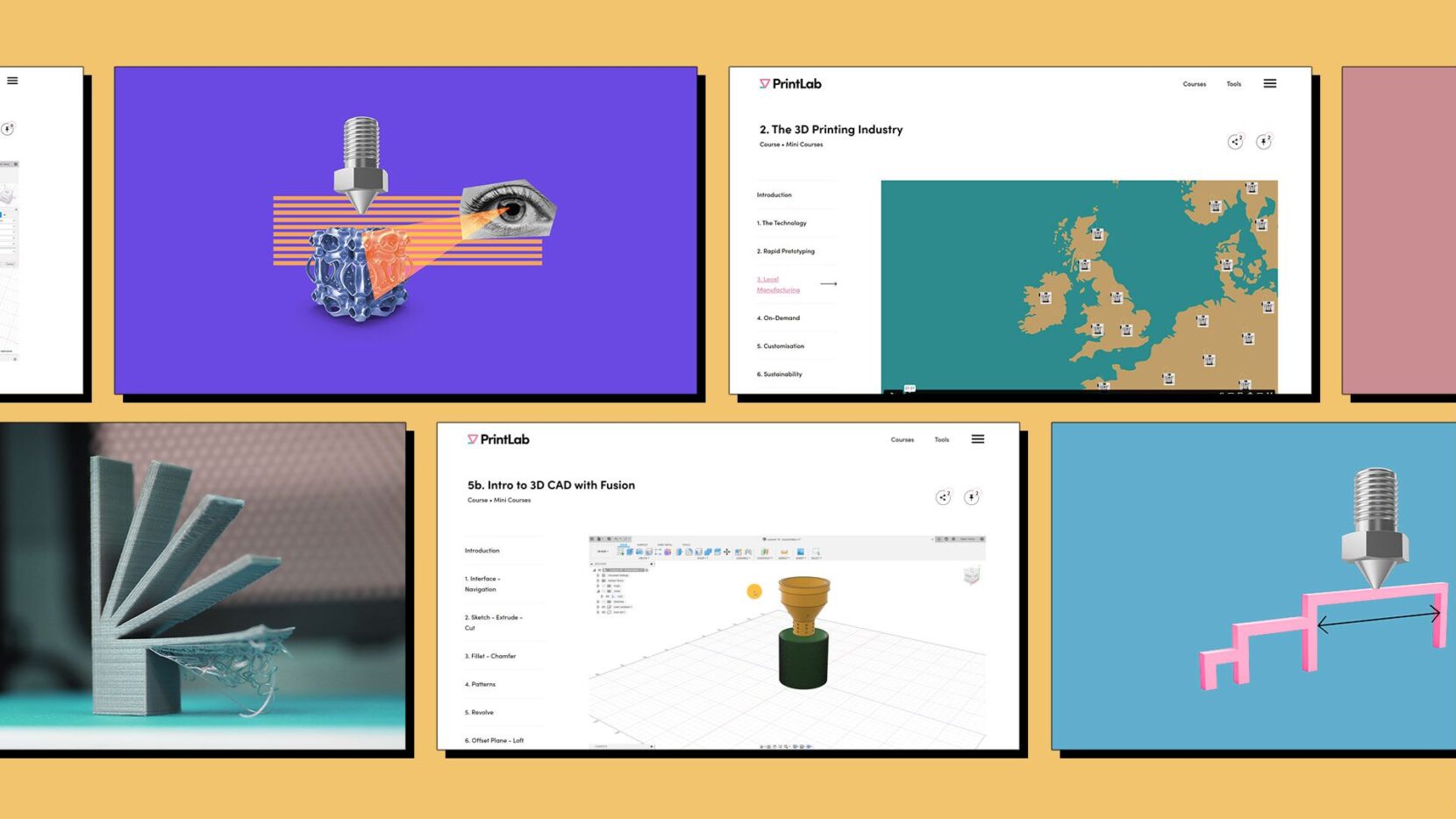

Throughout the blog, you’ll learn how Chris incorporates the PrintLab Certification Program into his classroom. You can learn more about the program here. And now over the Chris!

Hi PrintLab Community! I’m Chris Guthrie, a Product Innovation & Design teacher at Moorpark High School in California. I’m excited to share a glimpse into our past school year, where learners built skills through PrintLab’s Certification Program while applying them in a wide variety of design and 3D printing projects.

Instead of completing the certification all at once, we wove it into the rhythm of the year. Learners would explore short PrintLab lessons or mini-courses as we launched new projects, then put their knowledge to work immediately in context.

For example, when a unit required CAD skills, we drew from PrintLab’s tutorials on design fundamentals. When we tackled projects with a focus on sustainability, we connected to PrintLab’s methods for design thinking and product development.

This blended approach made the certification program a living resource in our classroom. Rather than being a checklist item, it became a set of tools learners could draw from again and again, each time with a deeper understanding. By the end of the year, many had earned their Maker certification, but more importantly, they developed the confidence to tackle complex problems and express themselves through design.

Most of our projects were framed through the lens of sustainable product design, encouraging learners to think like innovators preparing to launch real products. Below are some highlights of the work that came out of this journey.

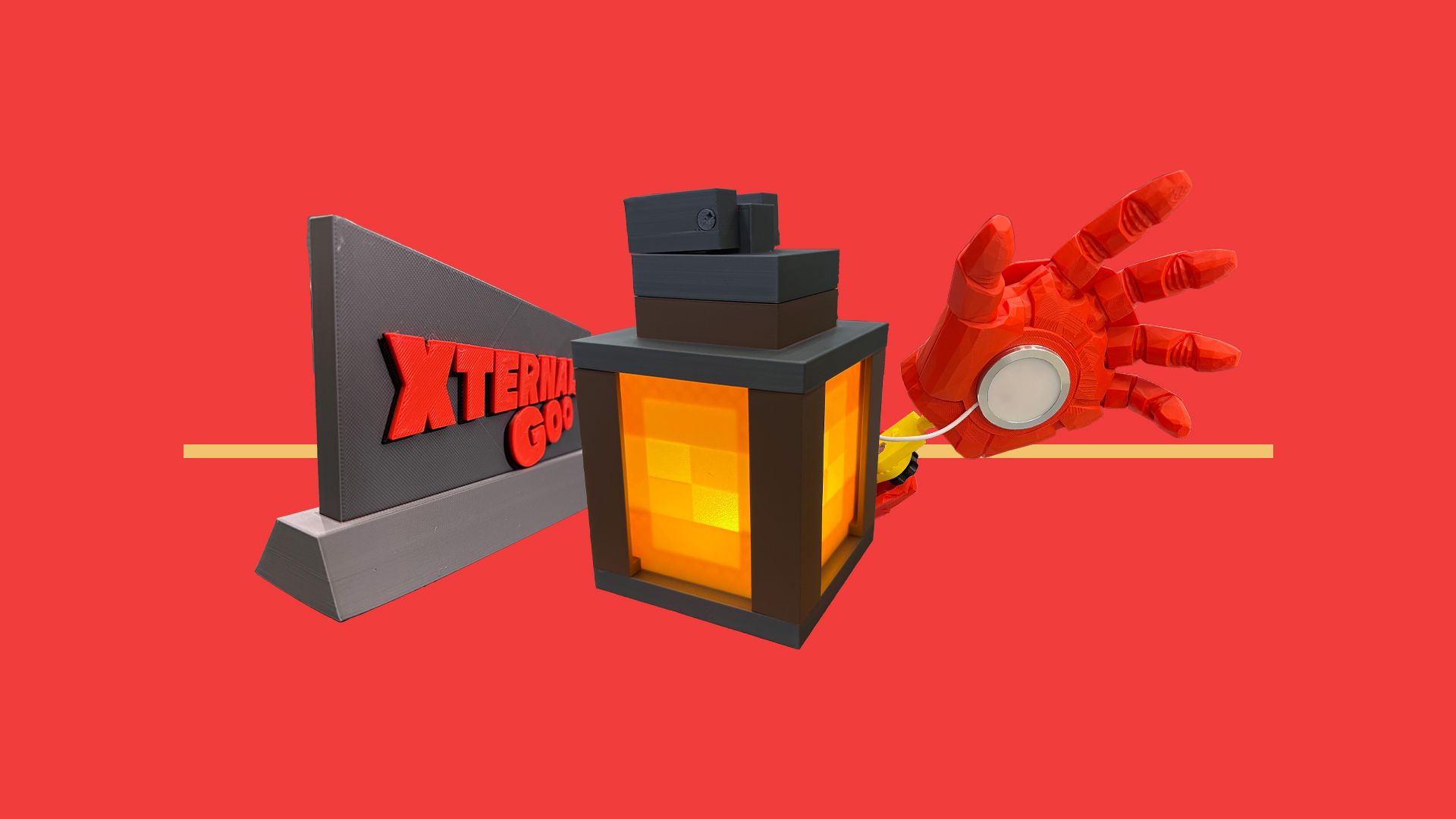

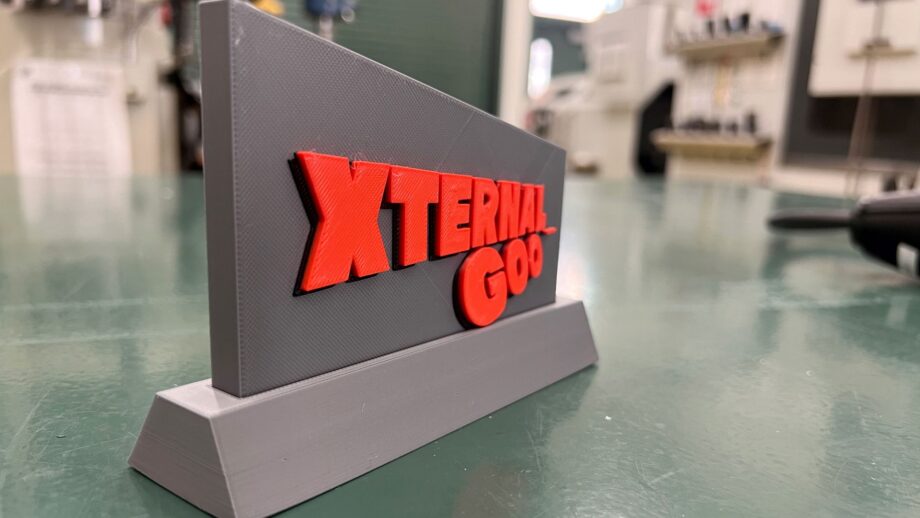

3D Printed Typography

One of the first projects my learners completed was PrintLab’s 3D printed typography course, which quickly became a favorite. It gave them voice and choice in their designs while introducing foundational concepts of font and color theory. I also added a layer of technical skill by teaching learners how to convert image files into SVG vector graphics, an important step that opens the door to more advanced design work.

Typography proved to be a powerful entry point into CAD. It was approachable but still required learners to practice layering, alignment, extrusion, and tolerance. Many also explored multi-color printing through Bambu Studio, giving them early experience with advanced workflows used in real-world manufacturing. Most importantly, this project allowed for personal expression. Learners created work that reflected their identities, interests, and sense of humor, which kept engagement high and brought an extra level of creativity into the classroom.

The final results were impressive: custom desk signs, nameplates, and fandom-inspired keychains. Beyond the physical products, learners came away with a deeper understanding that design is not only about function but also about storytelling and branding.

Imaginative Play Toy Sets

Around the holiday season, our classroom came alive with one of the most memorable projects of the year: creating imaginative play toy sets for children ages 4–8. Learners worked in small groups to design cohesive toy collections that balanced creativity with safety and functionality.

The major focus of this unit was product safety. We studied toy standards and applied them directly by performing hands-on safety tests with each printed piece. This gave learners an authentic perspective on the responsibilities that come with designing products for children.

Packaging was also a key component of the project. Each group received a gift box and decorated it with markers and paint to reflect the spirit of their toy set. They also designed product insert cards that highlighted the features and benefits of their toys, building on marketing and communication skills we had developed in earlier units.

The culmination of the project was both meaningful and memorable. Learners donated their finished toy sets to children in need within our community. In post-project surveys, nearly every learner chose this as their favorite unit of the year because of the strong connection it built between their design work and giving back. Many described the experience as “warm and fuzzy” — a reminder that design and engineering can be powerful tools for empathy and community impact.

Coaster Mold Project

In this project, learners designed and 3D printed their own coaster molds, a challenge that required precision and an understanding of clearances and fit. The focus of this unit was sustainability and manufacturing strategy, where learners explored when it makes sense to create a reusable mold for larger production runs compared to directly 3D printing a short run of parts.

While the original PrintLab lesson used mycelium spores to grow coasters, we adapted the activity for our classroom by recycling cardboard as the casting material. This adjustment connected perfectly with our sustainability goals and encouraged learners to think critically about material reuse and waste reduction.

The project also pushed learners to refine their CAD skills. They had to ensure their two-part molds aligned properly during the forming process and consider important design elements such as draft angles, wall thickness, and release features. These are the same factors used by engineers and designers in professional manufacturing settings.

After completing the coasters, we extended the discussion to pulp molded protective packaging, examining how similar mold design principles are used in industry to create sustainable packaging for electronics and consumer products. This connection helped learners see the broader applications of their work and understand how eco-conscious design translates to real-world manufacturing challenges.

By the end of the unit, each learner produced a functional mold and a recycled cardboard coaster that demonstrated both creativity and technical accuracy. The experience helped them see that 3D printing is not only a way to make final products but also a powerful tool for creating the tools needed in sustainable, scalable production.

Lit in Motion Project

The Lit in Motion project combined creativity, mechanics, and functional design in a way that truly captured my learners’ attention. To start, we explored a series of 3D printed mechanism cubes from PrintLab’s mini course. Each cube demonstrated a different type of motion or mechanical principle, such as a hinge, cam, or gear system. Learners watched the tutorials, studied how the mechanisms worked, and then recreated the cubes themselves in CAD to reinforce their understanding.

With that foundation in place, we moved into the main design challenge: creating a desk lamp that incorporated at least one working mechanism. This phase required learners to think critically about how motion could be used to adjust, rotate, or extend parts of their lamp while maintaining a visually appealing and functional design.

We also introduced dovetail joints as a structural feature and a way to strengthen 3D printed parts. This concept helped learners think more deeply about print orientation, stress points, and assembly techniques, adding an important layer of engineering awareness to their creative process.

By the end of the project, learners had produced lamps that were both artistic and mechanically sound. Some featured adjustable arms, rotating shades, or sliding components that demonstrated how movement can enhance usability and design appeal. The project tied together many core skills from throughout the year—CAD precision, mechanical reasoning, and aesthetic design—culminating in a product that literally and figuratively brought their learning to light.

Launch an Amazon Store Project

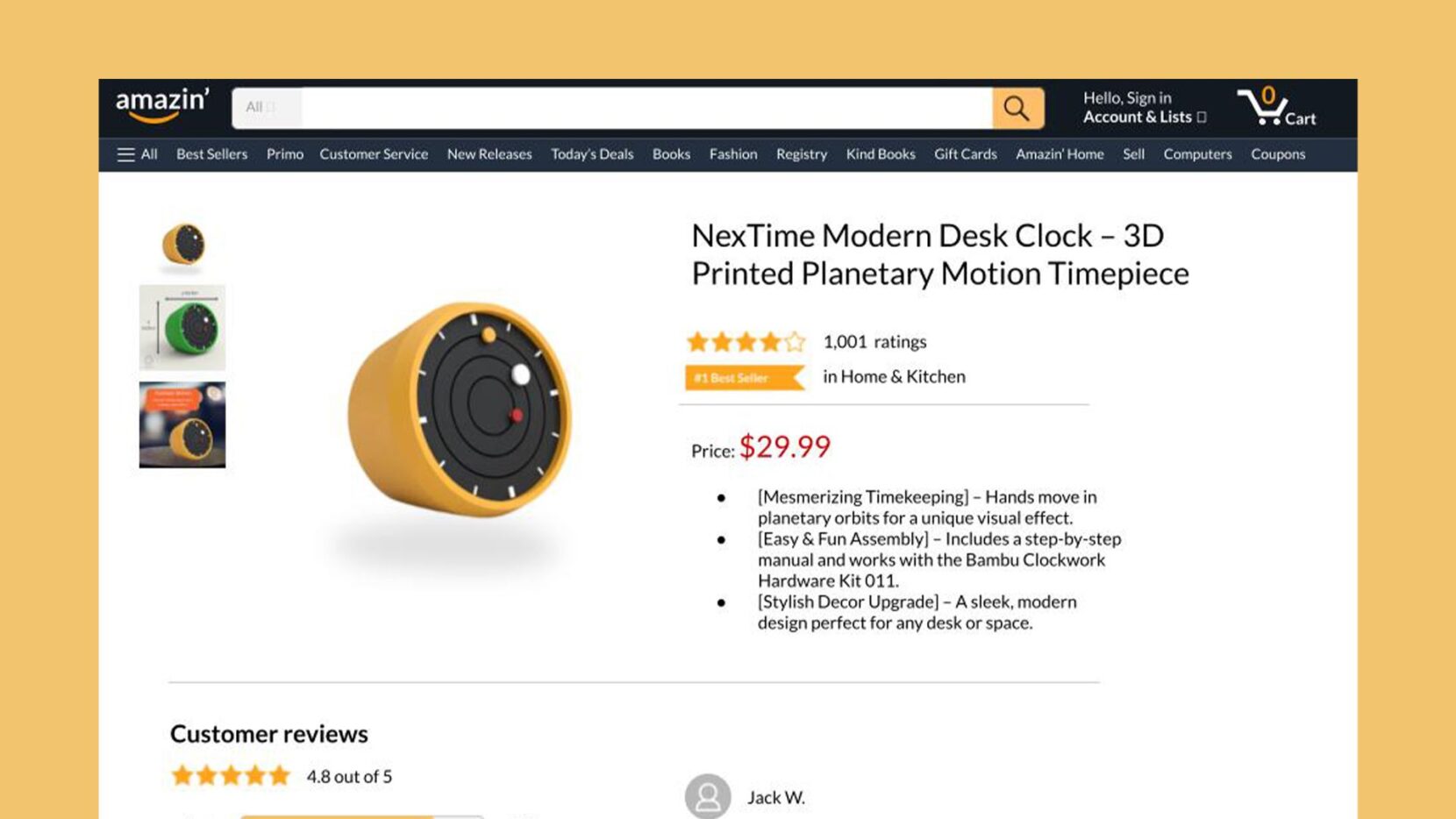

Our final major project of the year was Launch an Amazon Store, a large-scale simulation of what it takes to bring a product from concept to customer. This project pulled together everything my learners had practiced throughout the year—design, marketing, production, and communication—into one authentic experience that mirrored how modern product teams operate.

Working in small groups, learners developed a cohesive product line around a shared theme or target market. They refined their marketing skills by identifying product features and benefits, crafting persuasive descriptions, and designing visual branding that reflected their group’s creative direction.

What made this project especially powerful was the collaboration across classes. My learners partnered with the Photography and Media Productions programs on campus, outsourcing key tasks like product photography and commercial creation to peers who specialized in those areas. This experience gave them a real sense of how professional design and marketing teams function—communicating their needs clearly, providing creative briefs, and trusting experts to deliver high-quality results.

Throughout the project, we discussed the concept of outsourcing as a valuable skill in itself: knowing when to delegate work to people who can do it faster, better, or more efficiently than we can. This helped learners understand that being a designer or entrepreneur isn’t about doing everything alone—it’s about building and leading teams that bring a shared vision to life.

We also incorporated AI tools to refine product listings and support creative brainstorming. Learners used AI to improve their writing tone, test different headline variations, and even generate sample customer reviews to analyze what drives consumer trust and engagement.

The project culminated in the creation of faux Amazon product detail pages, complete with photography, marketing copy, and promotional materials. These pages served as digital storefronts for their ideas and demonstrated the power of collaboration, creativity, and communication. By the end, learners not only saw how a product comes to life but also experienced the reality of teamwork and strategic delegation—the kind of skills that will serve them well far beyond the classroom.

Reflection and What’s Next

Looking back on the past year, I’m incredibly proud of how far my learners have come. Each project—from Typography to Toy Creation to our full-scale Amazon Store simulation—built upon the last, layering creativity, precision, and purpose into every design. What I value most is how PrintLab’s curriculum allowed me to adapt professional-level design thinking into a high school setting, making complex concepts approachable and engaging.

The hands-on projects gave my learners opportunities to collaborate, problem-solve, and see how design impacts real people in real communities. They not only built products but also confidence, empathy, and an understanding of what it means to be part of a team.

As we move forward, I’m excited to take the next step in our program’s evolution. My Capstone learners will begin working in Autodesk Fusion, deepening their skills in parametric modeling and preparing for industry certification. We will also be incorporating the Make:able Assistive Technology Challenge, where learners will design and prototype devices that improve accessibility and independence for people with disabilities.

This next phase represents exactly what I love about teaching design and manufacturing—the blend of creativity, innovation, and social good. With PrintLab continuing to serve as a foundation for our curriculum, I can’t wait to see what my future learners will imagine and create.

A huge thank you to Chris for sharing this inspiring look into his classroom. Stories like this show how PrintLab’s resources can empower learners to think creatively, solve meaningful problems, and develop real-world design skills. If you’d like to bring similar projects into your own classroom, explore our curriculum, challenges, and certification pathways across PrintLab using the trial link below!

Learn more about PrintLab 3D printing certifications and curriculum with a free trial