Embracing Sustainable Design with Mycelium and PrintLab

Today we have the pleasure of sharing a guest blog written by our pioneer, Chad Pavlekovich. Chad is a STEM Educator at Salisbury Middle School (USA) and recently delivered our Mycelium Moulds 3D printing project to his 7th Grade students. During the project, students worked through the full creative process to make a range of products out of mycelium - the root-like structures of mushrooms. Over to Chad!

3rd July 2024 • Case Studies

Guest Blog by Chad Pavlekovich

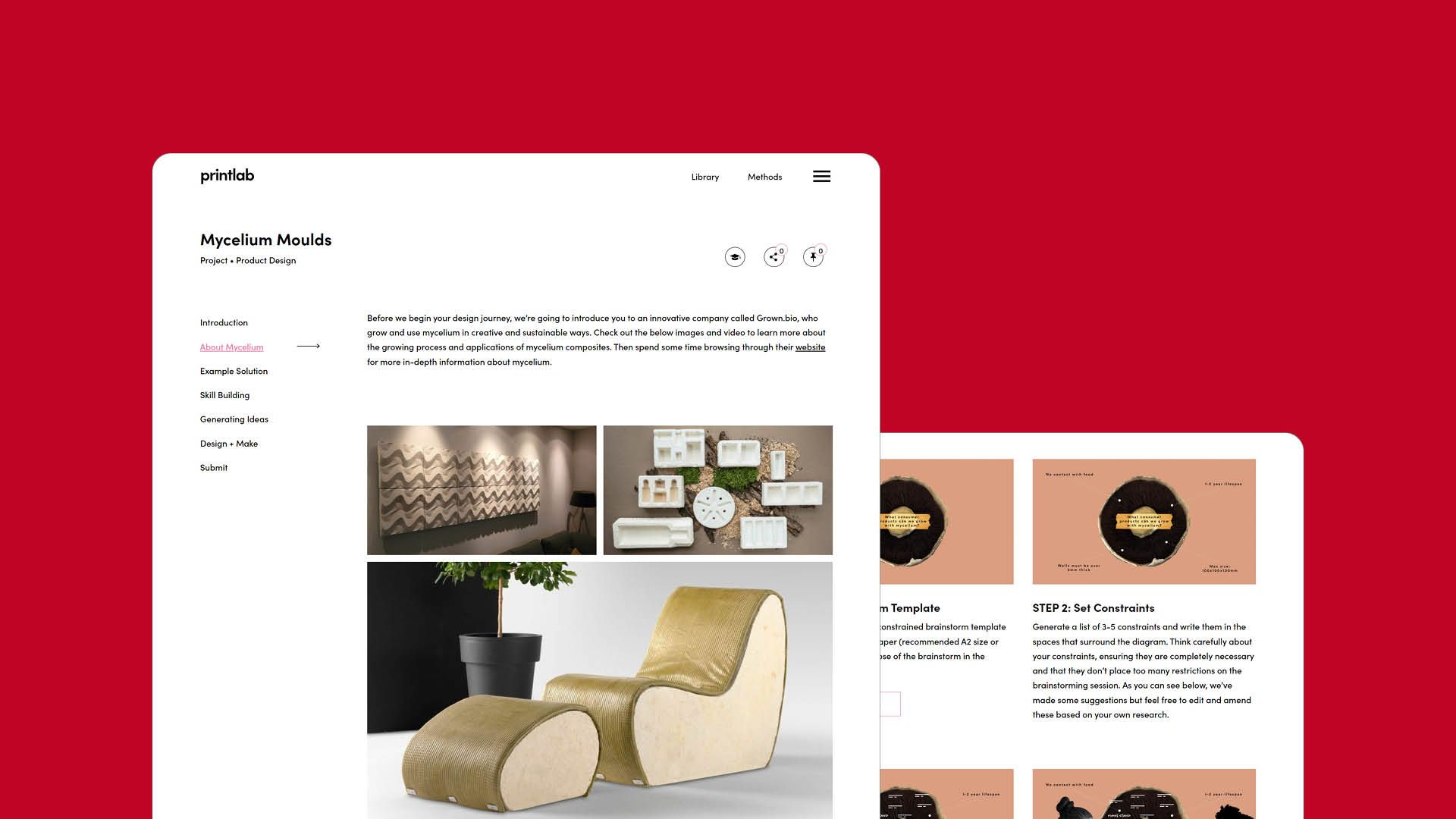

I had the opportunity to engage my 7th grade class (NeXgen STEM Academy) with a unique and, literal transformative journey which unfolded as students engage in an engineering design challenge working with living biomaterial while implementing the practice of sustainable design. This innovative project based on the PrintLab’s Mycelium Moulds project and the work of Grown.bio, seamlessly merges art and functionality, utilizing 3D printing, vacuum forming, and the growth of mycelium to create environmentally conscious products.

The premise behind this activity was to experience how technology and nature can offer a glimpse into the future of sustainable manufacturing, where creativity and ecological responsibility converge. The layout of this project provided a breakdown of the overall goal into various tasks/chapters (components). This allowed flexibility for teams to work independently of one another or collaborate to work through pitfalls and roadblocks. By approaching it from this perspective, it provided students with opportunities to set goals and experience pressure points in design and time management – all key elements required in fabrication of materials and products. Based on the general layout of the project, my class approached this challenge from the following prospective.

The Project: From Concept to Creation

We began the project with a look into the world of mycelium, the root-like structures of mushrooms known for their remarkable binding properties. Having acquired the mycelium from Grow.bio (https://grow.bio/), we allowed students to engage with the material to get a better understanding of what the resulting outcomes can be. Students in teams of 2-3 worked on their own designs by brainstorming potential consumer products, guided by the principles of sustainability, form, functionality and application.

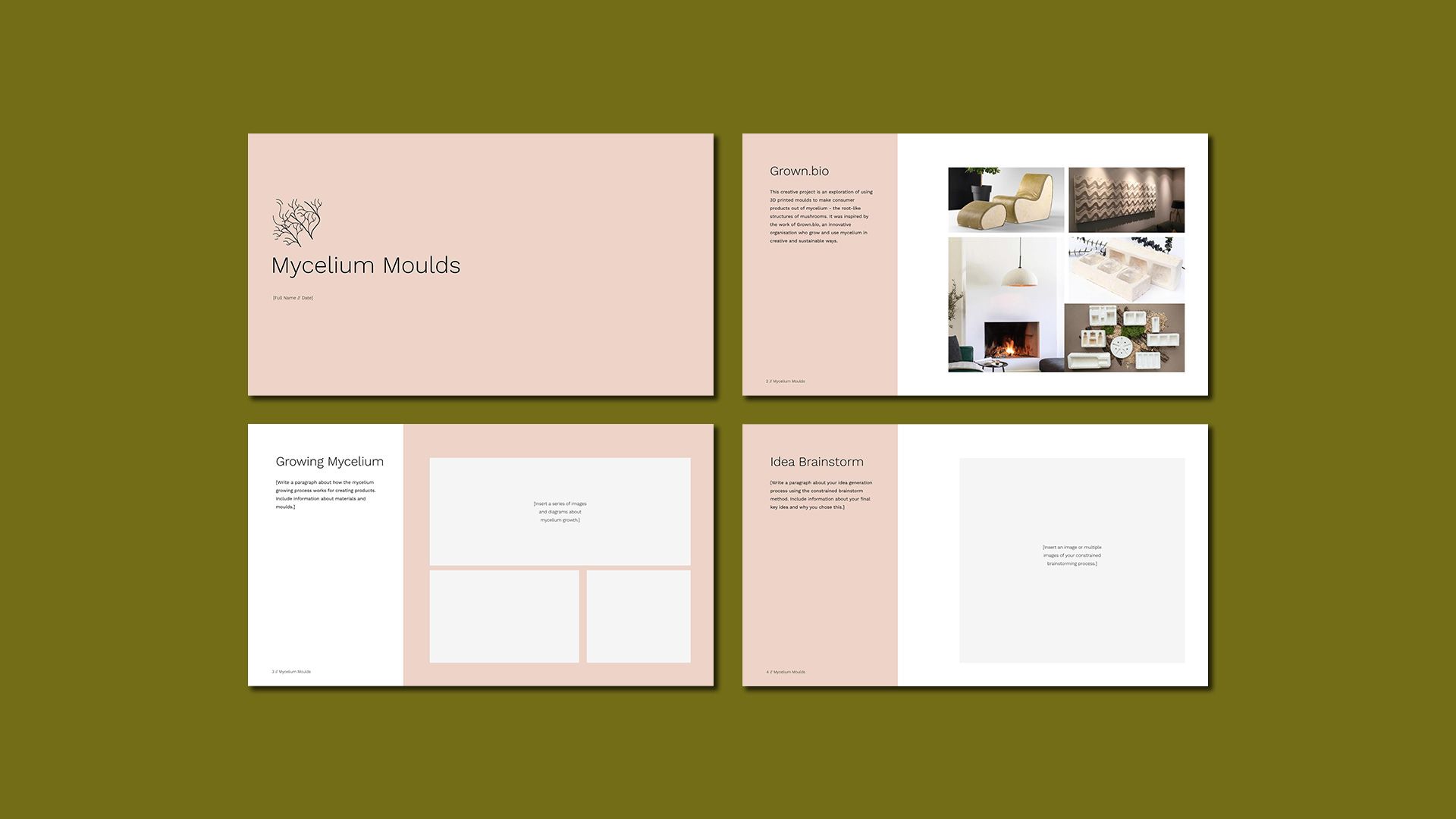

It does need to be mentioned that all of my teams utilized the project portfolio template provided on the PrintLab project platform. The template allowed my students to collectively record, share and submit their overall designs. This ideation phase was crucial as it sets the stage for the subsequent design and manufacturing processes.

Brainstorming and Ideation

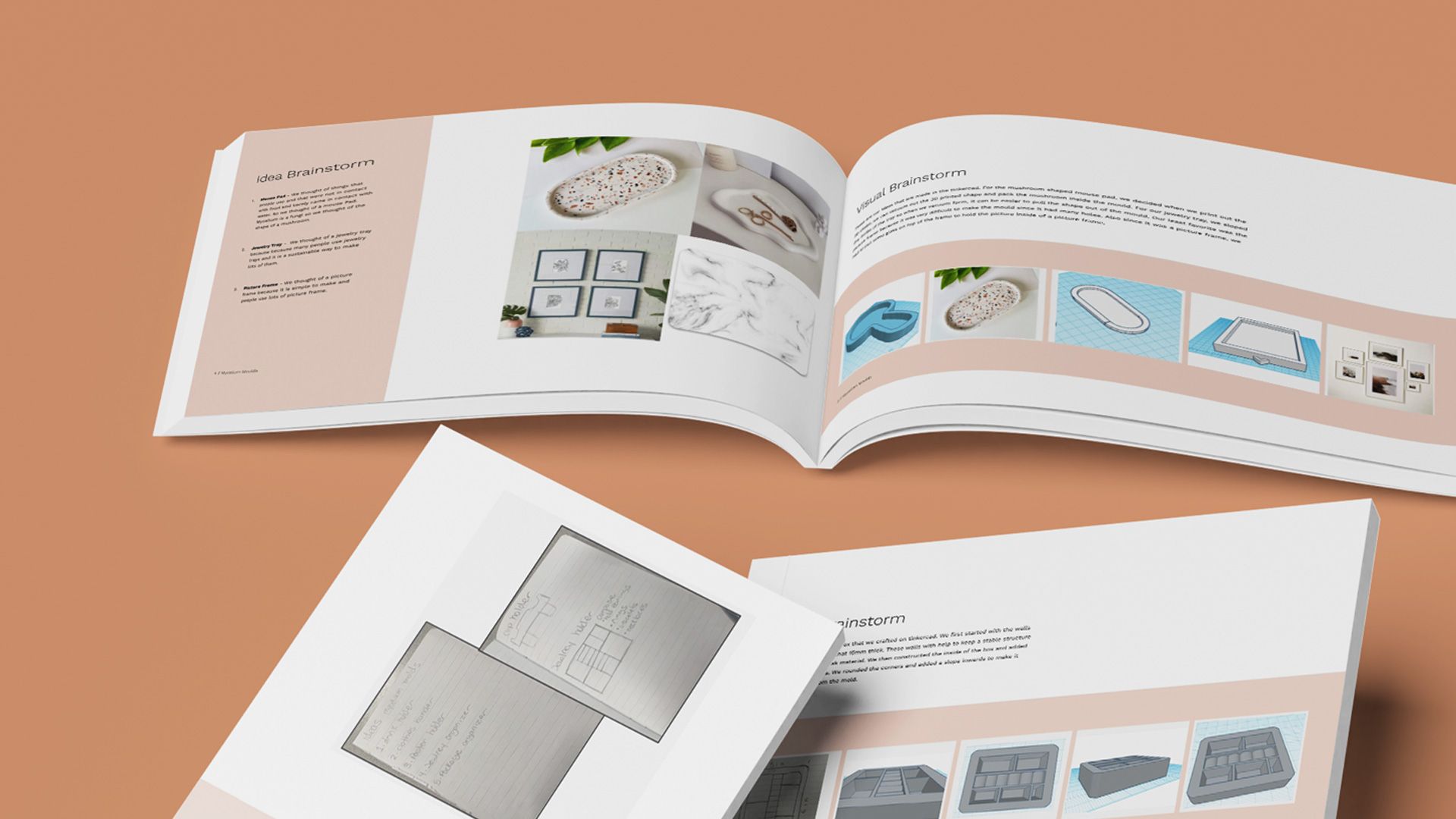

• Written Brainstorming: Students started by identifying feasible and desirable consumer products that can be made from mycelium. This involved considering everyday items that could benefit from sustainable design. A written rationale was comprised to provide a narrative for moving forward, based on research and team decisions.

• Visual Brainstorming: Through sketches (multi-view) and digital designs on Tinkercad, students refined their ideas, ensuring they met the project’s criteria and constraints, such as reusability and minimal exposure to water and food. These criteria were essential to their understanding of the need for their designs to be more than just a “one-off” piece/design.

Designing and 3D Printing Moulds

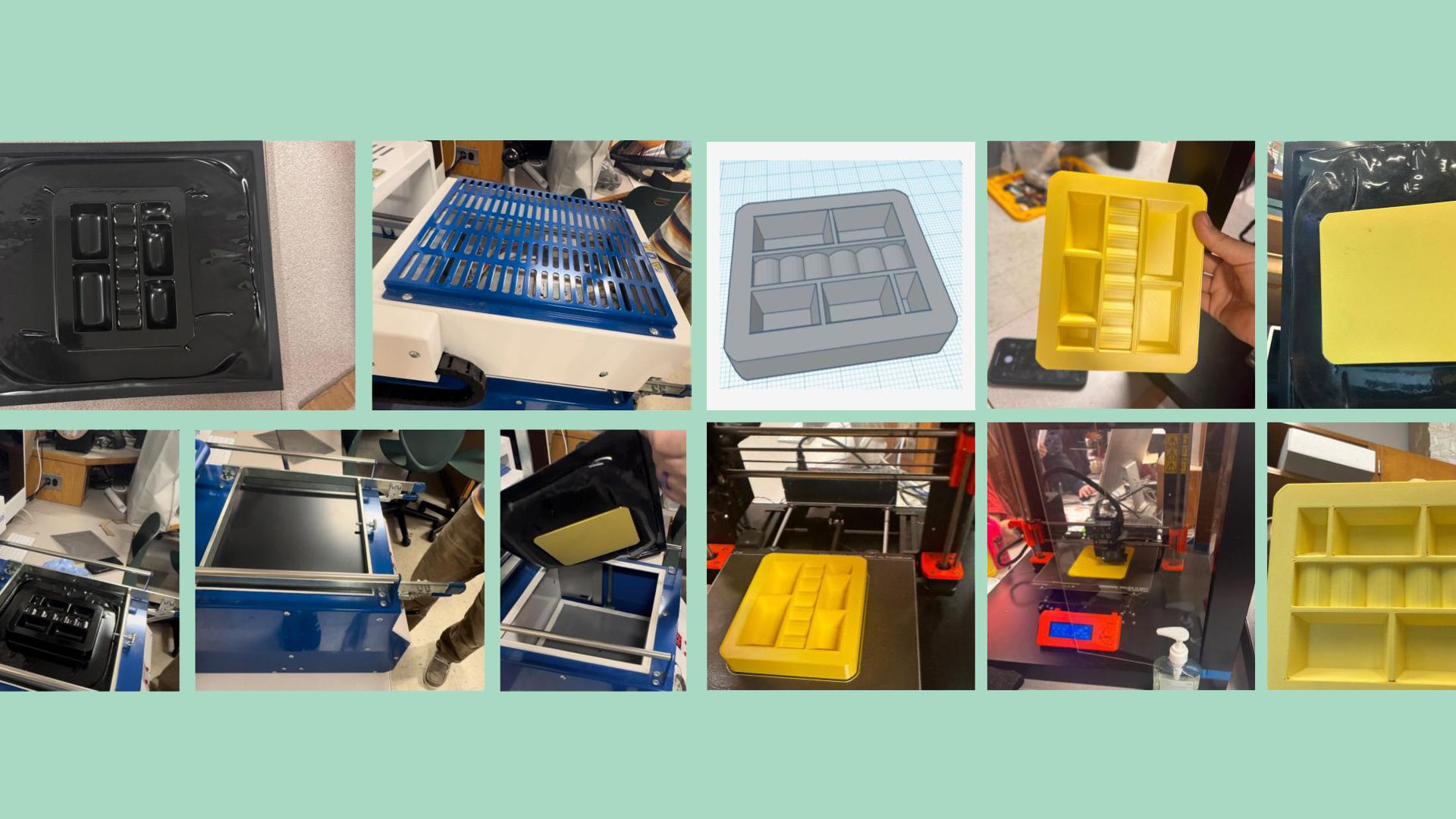

The next phase involved translating these ideas into tangible designs using Tinkercad. Students created 3D models of their products, paying close attention to the design constraints. Key considerations included: ensuring a minimum wall thickness of 15mm and incorporating draft angles to facilitate the easy removal of the final product from the mould. It needs to be mentioned that not all of the team’s designs were vacuumed formed, some teams elected to create 3D printed moulds, which provided additional diversity of design. This also supports the ability to complete this project without the use of vacuum forming if that equipment is not available to use.

• 3D Printing: The digital designs are brought to life through 3D printing, resulting in precise and reusable moulds.

• Vacuum Forming: These 3D printed moulds are then used in the vacuum former, where heated plastic sheets are moulded to the desired shape, creating sturdy forms ready for mycelium growth.

Growing Mycelium

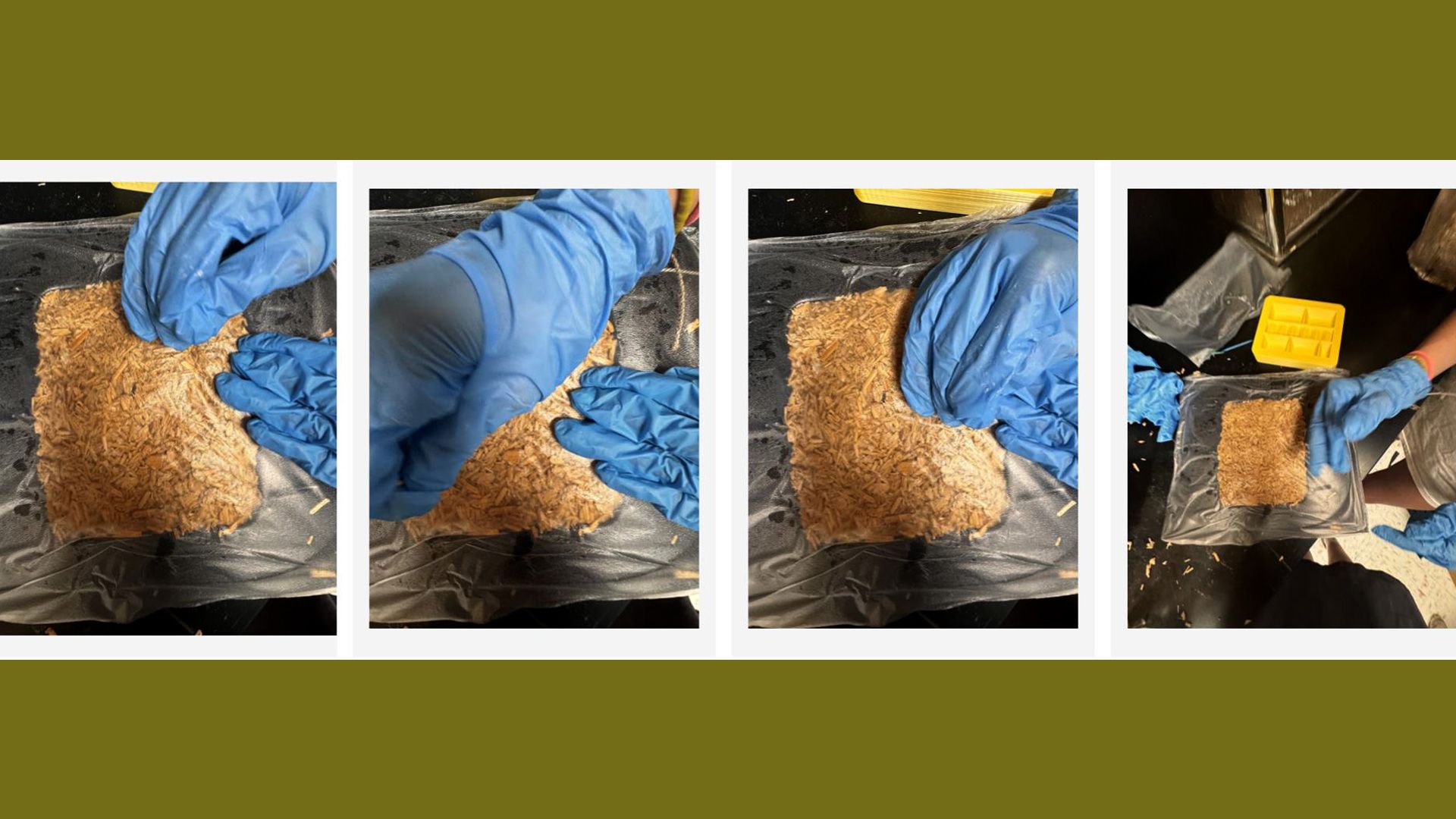

The core of this project lies in the biological process of growing mycelium. We used the suggested Grow it Yourself mycelium packages to create our designs. The overall process of growing the mycelium was straight forward (Grow.bio has a great manual and tutorial videos to aid in this process). The vacuum-formed moulds were packed with a mixture of mycelium and organic substrate. Over a period of 3-5 days, the mycelium grew, binding the substrate together to form a solid and eco-friendly product.

• Preparation and Packing: Students meticulously prepare the mycelium mixture, ensuring the right consistency for optimal growth. The mixture is then tightly packed into the moulds.

• Growth Monitoring: Throughout the growth phase, students monitor the development of the mycelium, observing how it colonizes the substrate and transforms into a robust material.

Challenges and Learning Experiences

This project is not without its challenges. Students faced various obstacles, from perfecting their 3D designs to ensuring the mycelium grows uniformly within the moulds. These hurdles, however, are integral to the learning process, fostering problem-solving skills and resilience.

• Design Adjustments: Initial designs often required modifications to meet the practical requirements of mycelium growth and mould extraction.

• Growth Management: Maintaining the right environmental conditions for mycelium growth is crucial. Students learn the importance of cleanliness, temperature control, and proper aeration to prevent contamination and ensure healthy growth.

Reflections and Outcomes

The culmination of this project is not just the creation of sustainable products but also the invaluable lessons learned by the students. They gained hands-on experience in sustainable manufacturing practices and a deeper understanding of ecological responsibility.

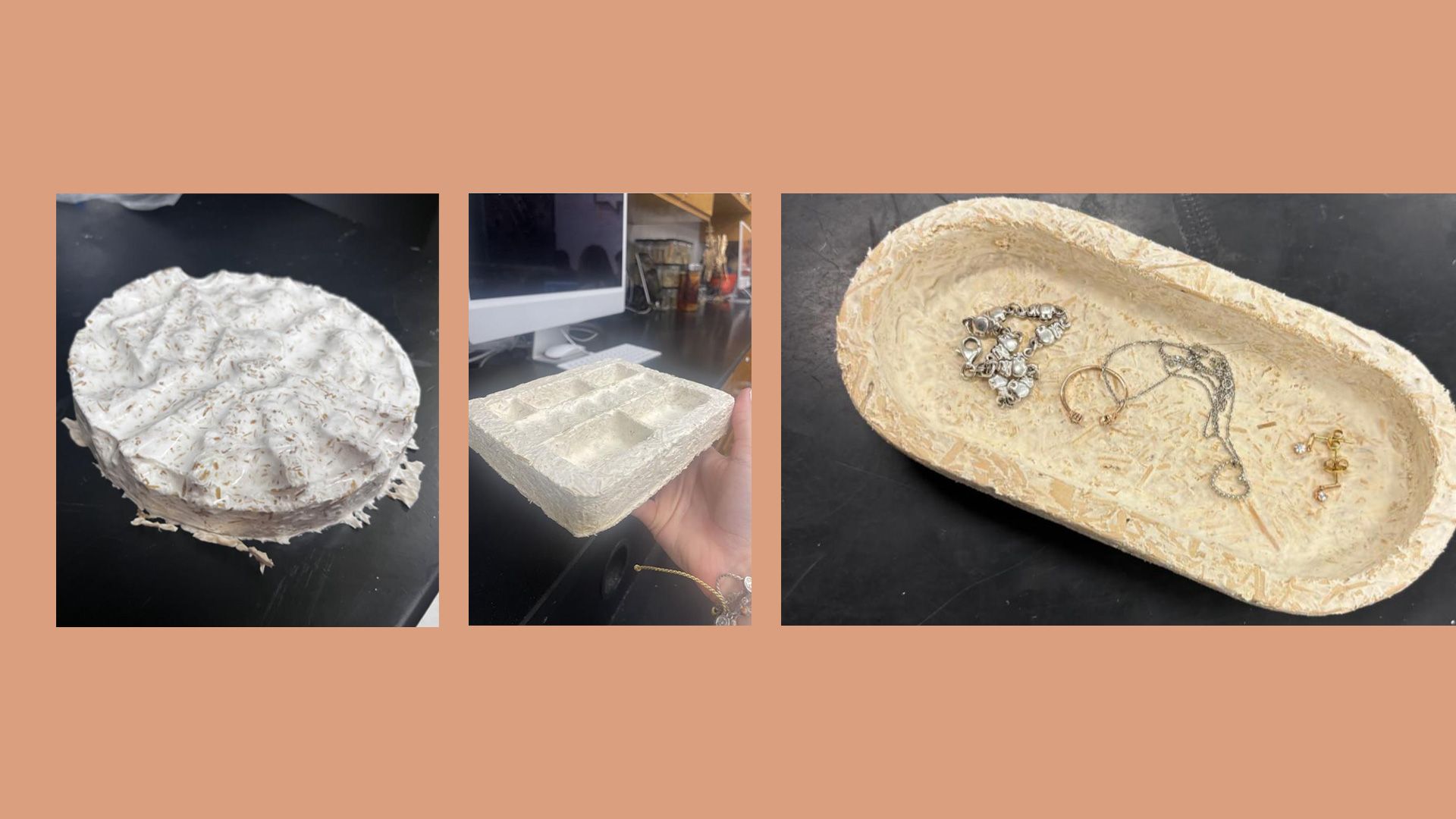

• Final Products: The end products, ranging from jewelry holders to decorative art pieces, are a testament to the students’ creativity and dedication to sustainability.

• Educational Growth: Students reflected on their journey, acknowledging the importance of interdisciplinary knowledge that spans biology, engineering and environmental science.

To truly capture the essence of this project, here is an example portfolio from the project, which shows the entire design process – from the initial brainstorming sketches to the final mycelium product.

Conclusion

My students experience with the mycelium moulds project exemplified the power of combining technology with nature to create sustainable solutions. As my students navigated the complexities of design and biology, they were not just building products; they were crafting a vision for a sustainable future. This project is a beacon of innovation, demonstrating that with creativity and determination, we can help the youth of today forge a path towards ecological harmony and responsible manufacturing.

This is a project that is a bit more challenging, however, I believe it can be accomplished by educators and students that want and can accept challenges, adapt to current circumstances surrounding the activity, adjust and pivot where needed and engage in the engineering design process. Through this, there is ample opportunity for all participants to learn and have fun through creativity, science and engineering.

—

A huge thank you to Chad for sharing his experience with us. The creativity shown by his students is truly fantastic and we look forward to welcoming Chad back to the blog again soon! If you’d like to check out the mycelium project for yourself, get started on a free trial to PrintLab using the link below.