PrintLab’s 3D Scan of the Week 1 – Sea Shell

We’ve recently teamed up with Shining3D to bring 3D scanning to schools around the world, and today we’re excited to announce a new weekly feature from PrintLab – Scan of the week. Each week we’ll be uploading a new 3D scan that will be available to download completely free!

14th March 2017 • News

Our first 3D scan is a sea shell, scanned by the EinScan-S 3D scanner, which uses innovative structured light technology to create amazingly accurate scans in just a few minutes.

The 3D Scanning Process

We placed the sea shell onto the EinScan-S turntable, selected a brightness setting and clicked “start scan”. In as little as 3 minutes, the first scan was created. In order to gather more scan data, we placed the shell at a different angle and started a second scan. After another 3 minutes our second scan was finished and EinScan’s software automatically stitched the 2 scans together.

The final step was to “mesh” the scan, which resulted in a fully watertight, 3D printable STL file. Not bad for less than 10 minutes work!

What can be done with this 3D scan?

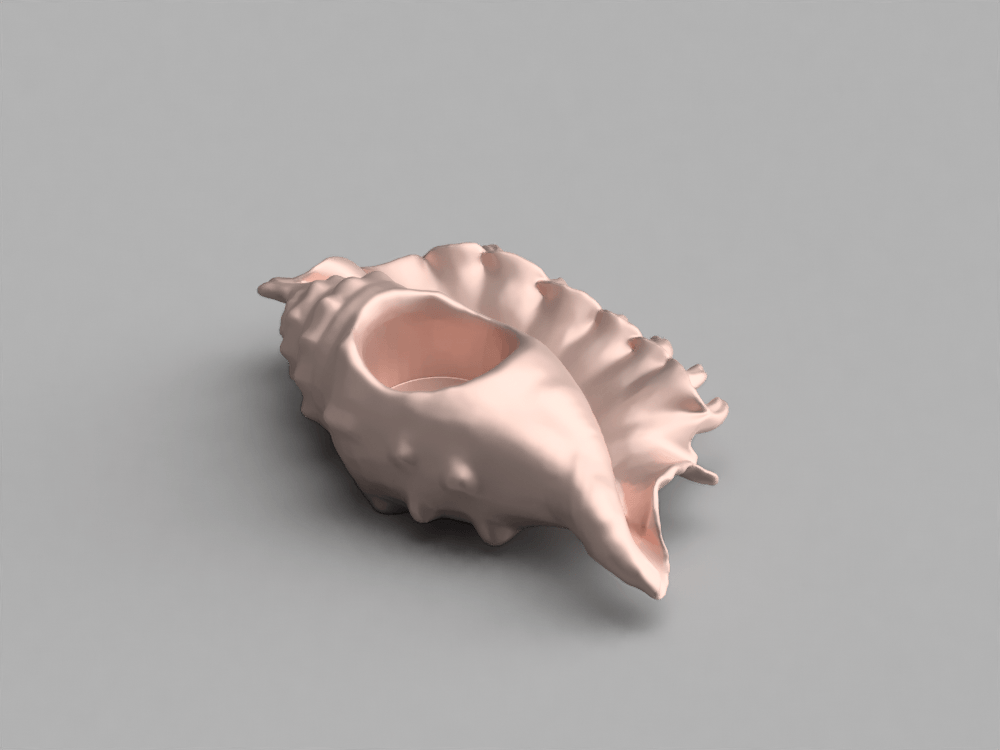

By acquiring a 3D scan of the sea shell, we open up a wide range of opportunities. Whether you want to recreate the shell in a different material, use it for animation or edit the model; all this can be done with 3D scanning. We decided to edit the shell scan to create an organic candle holder, here is a render of our creation.

We also 3D printed our design, and here is the outcome:

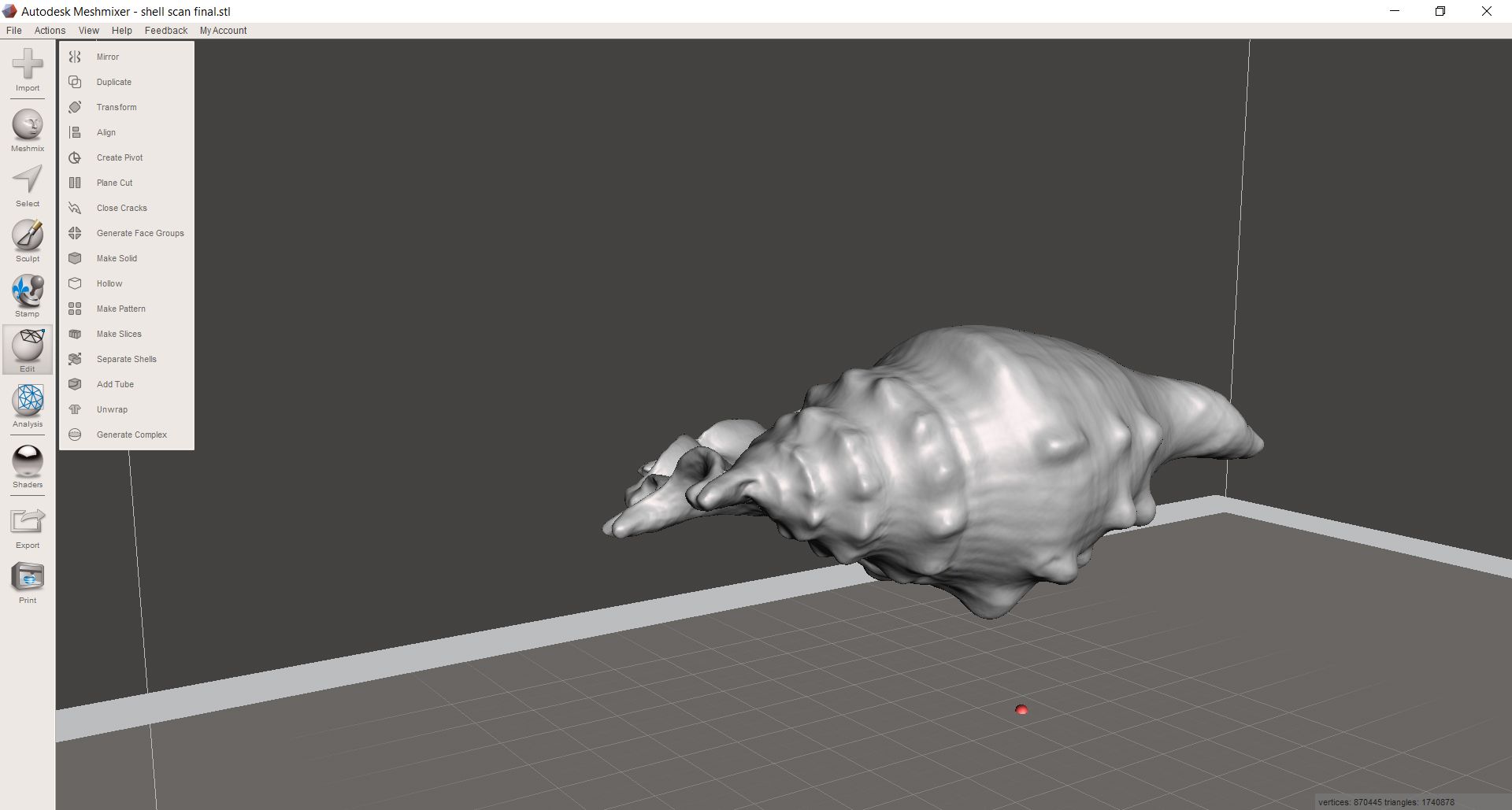

Manipulating the 3D scan was quite an easy process and done using the free software Meshmixer. We scaled the 3D model up and put a flat edge on the bottom so our candle holder would stand up. Then we cut a hole in the main body of the shell, where our candle would sit neatly.

You can also download the model for free from our Sketchfab page here: www.sketchfab.com/weareprintlab

**Please note that 3D print was produced in PLA, which is not a safe material to use near flames. It was created as a decorative prototype therefore if your recreate this model, be sure to check the technical data of the material you choose**