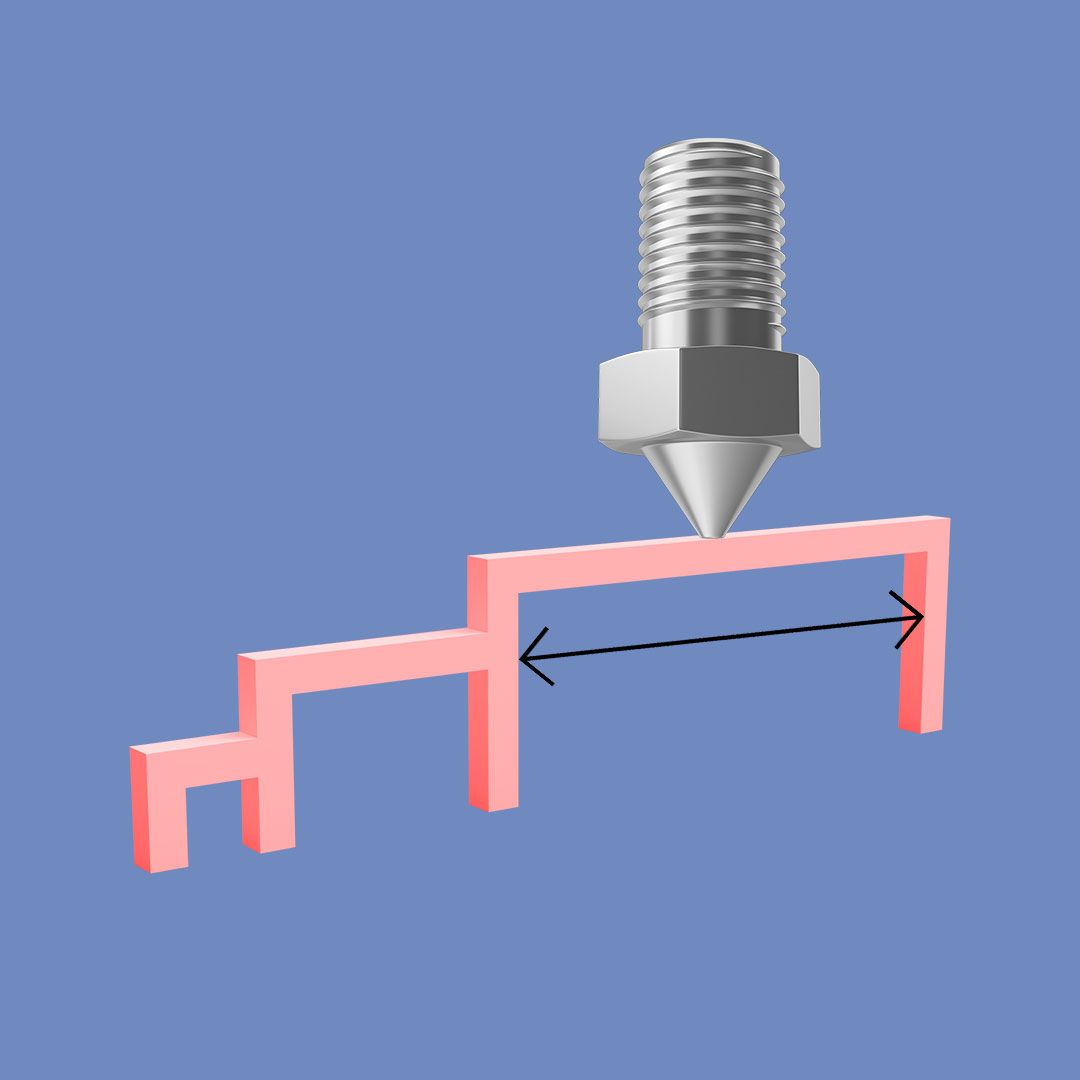

8. Connections + Mechanisms

Mini Course . Advanced . 3 Hours

Learn how to incorporate connections and movement in your models using this growing library of 3D printed mechanism tutorials

Course

Learn how to incorporate connections and movement in your models using this growing library of 3D printed mechanism tutorialsMini Course . Advanced . 3 Hours

Course

Learn 10 top tips for designing specifically for 3D printing - ensuring your models are printable and optimisedMini Course . Beginner . 1 Hour

A code is a combination of letters and numbers that gives you access to PrintLab’s Student Portal. If your school or organisation is signed up to PrintLab Classroom, simply ask them for the code and enter it above. If you’re an educator and not sure where to find your code, click here.

For any support queries or general questions, please email hello@weareprintlab.com and we’ll be happy to help!