3D Printed Assistive Technology at Orangewood Christian School

In today’s blog, we are joined by our pioneer teacher, Brandon Hazzard, who recently introduced his students to the design and manufacture of 3D printed assistive devices. Brandon not only used PrintLab curriculum to support their journey, but also took a field trip to an inspirational organization to help students build knowledge and empathy for people with disabilities. Check out the interview below.

10th June 2024 • Case Studies

Hi Brandon. Great to have you on the PrintLab blog today! Can you begin by telling everyone who you are, what you teach and how 3D printing is used at your school?

My name is Brandon Hazzard and I am the Innovation Lab instructor at Orangewood Christian School in Maitland, FL. During the day I teach Sphero robotics, Tello Drones, Media Production, Swift Coding and our Fablab course.

Currently, since this is a new course for our school, the Fab Lab is designed to introduce our students to laser cutting, 3D printing, vinyl cutting and CNC routing to create a variety of creative projects.

It was fantastic to see that your students participated in our assistive clips project. We’ll get on to the project later but firstly, can you tell us why you chose to introduce students to the world of 3D printed assistive technology?

Introducing students to the world of 3D printed assistive technology aligns perfectly with Orangewood Christian’s vision and goals for fostering creativity, critical thinking, and community engagement. By exploring 3D printed assistive technology, students are encouraged to think innovatively and creatively. Unlike printing typical trinkets, designing assistive devices challenges students to consider real-world problems and develop practical solutions. This pushes them to think outside the box and apply their knowledge and skills in new and meaningful ways.

Partnering with local organizations or programs in the community adds a layer of authenticity to the learning experience. By working on projects that directly impact the lives of others, students develop a deeper understanding of the real-world applications of their skills and knowledge. This fosters empathy, social responsibility, and a sense of purpose in their education.

Printlab’s Ready-to-Go Projects: Utilizing Printlabs ready-to-go projects streamlines the design process and provides students with structured guidance while still allowing room for creativity and customization. It also encourages them to actively participate in the design process, make modifications, and iterate on their projects to achieve the best possible outcomes.

Overall, introducing students to 3D printed assistive technology not only equips them with valuable technical skills but also cultivates important qualities such as empathy, innovation, and community engagement. It offers a meaningful way for students to connect with the world around them and make a positive impact through their education.

Prior to the project, we understand that students took a field trip to GO Baby Go on the campus of the University of Central Florida. What is GO Baby Go and what did the students gain from going on this field trip?

The mission of UCF Go Baby Go! is to provide innovative, accessible, and practical options to improve the lives of individuals with limited mobility. UCF Go Baby Go! is dedicated to interdisciplinary research, community outreach, and advocacy for children and adults with motor impairments. Our goal is to provide meaningful opportunities for mobility, participation, and play for individuals of all abilities.

The students were exposed to the world that most aren’t familiar with, students and adults with physical or motor impairments. They experienced that even though there are assistive technologies available, many are not affordable to everybody and so, Go Baby Go works with families and organizations to find more affordable, yet innovative solutions.

The main part of the trip was to help construct and decorate a motorized car so that they can play outside with their family like everybody else. So the students helped construct safety rails and seats for the vehicle as well as custom decorating the vehicle. Our students used the skills from our Fablab to vinyl cut logos and decals for the car.

They not only were able to learn about the program and what it is about, they were also able to make a difference in a local family.

And now on to the assistive clips project! Can you explain what the project was and the process students went through?

The project stemmed from the students’ experiences during a field trip to Go Baby Go. This exposed them to the challenges faced by individuals with mobility issues and inspired them to create solutions.

After the field trip, the students collectively decided to focus on creating assistive devices for individuals with arthritis or neuromuscular disorders. This decision was formed by the experiences and insights gained during the field trip. Students began by identifying everyday activities that could be made easier or more accessible for individuals with arthritis or neuromuscular disorders. This step helped them narrow down their focus and determine the specific tasks their assistive devices would address.

With a clear understanding of the target users and their needs, students researched arthritis and neuromuscular disorders to better understand the challenges faced by individuals living with these conditions. They then used Tinkercad, a 3D modeling tool, to design their assistive devices.

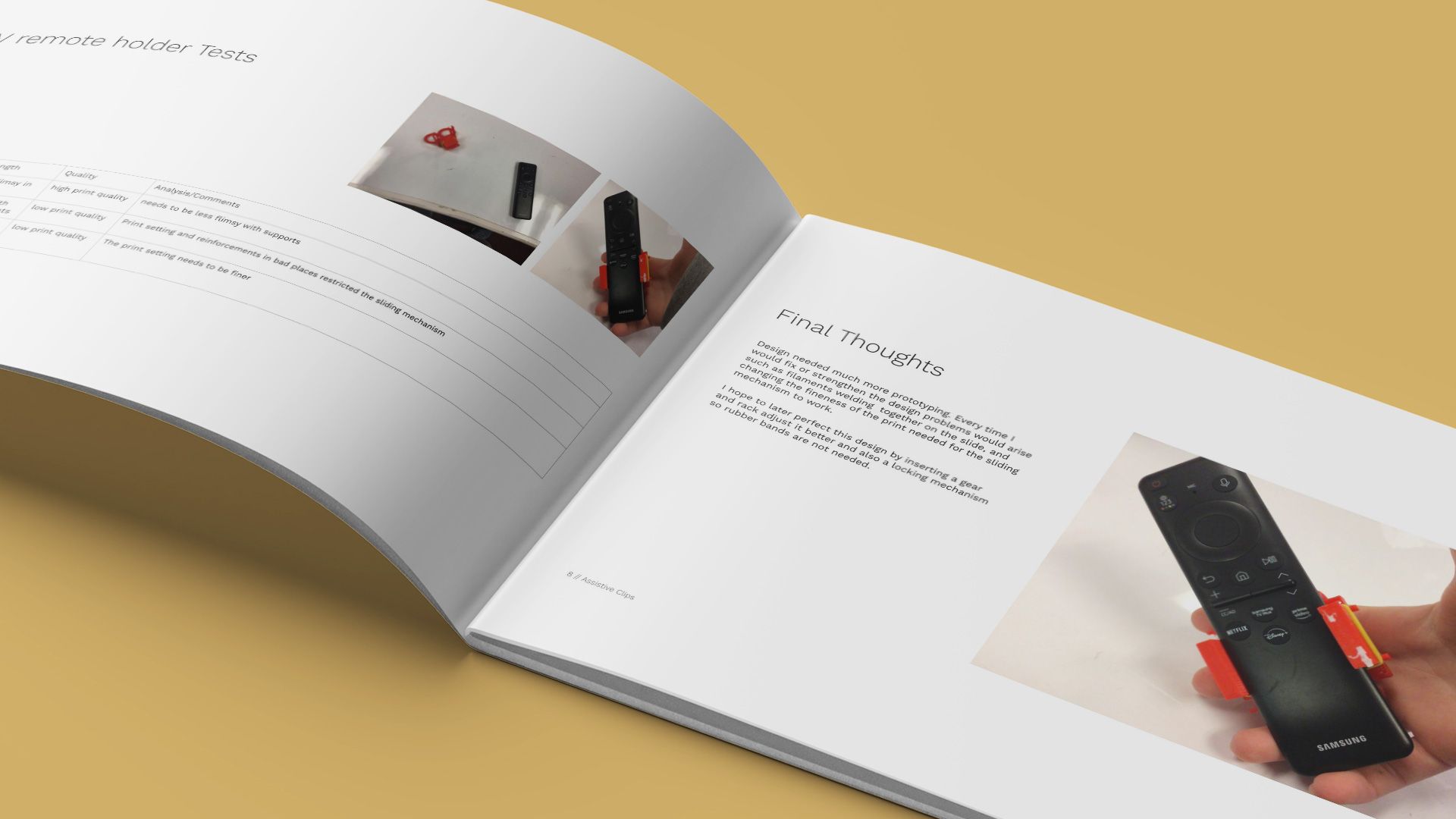

The designed files were sent to Dremel 3D45 3D printers to create prototypes. Once the prototypes were ready, students examined them, identified areas for improvement, and documented necessary changes. This iterative process involved multiple rounds of prototyping and refinement to ensure the final product met the users’ needs effectively.

After finalizing their designs, students conducted a day of testing where they swapped and tested each other’s products. This hands-on testing allowed them to evaluate the usability, effectiveness, and comfort of their assistive devices in real-world scenarios.

Throughout the entire process, students documented their progress, including design iterations, testing procedures, and final evaluations. This documentation included written notes, and photographs of their experiences and insights. Additionally, students reflected on their design process, considering what worked well, what could be improved, and what they learned from the project as a whole.

Overall, the Assistive Clips project provided students with a valuable opportunity to apply their STEM skills and creativity to address real-world challenges, while also fostering empathy and understanding for individuals with disabilities.

What types of designs did they create?

Students designed an assortment of projects ranging from seat belt clips, knife holders, food cutting devices, door knob grippers, smartphone holder, zipper gripper, bottle opener, and a few other items.

How did the PrintLab platform help you as a teacher in facilitating this project?

The PrintLab platform provided several key benefits to me as a teacher in facilitating the Assistive Clips project:

- PrintLab offered a structured portfolio example that allowed students to plug and play. This project sample provided students with step-by-step guidance on the project from start to finish.

- PrintLab’s ready-to-go projects saved our class time and effort in planning and preparation. Instead of having to create project materials from scratch, we could leverage PrintLab’s pre-designed project resources, and design templates, to easily integrate 3D printing projects into our classroom curriculum.

- PrintLab also provided access to a community of educators and 3D printing enthusiasts, allowing them to see other ideas, and learn from their experiences.

Finally, what’s next for your students? Any exciting upcoming projects?

We are finishing up the year so, this group of students will move on, but what we were able to accomplish was to form a lasting partnership with Go Baby Go. Go Baby Go have certain needs to be filled in the area of creating assistive technology devices for their families that they serve, and Orangewood students have a meaningful educational experience. We plan to reach out to more programs and community organizations to provide an experience that not only is educational, but one that is impactful.

—

A huge thank you to Brandon and his students for sharing their experiences with us! If you’d like to participate in the assistive clips project yourself, check out the free trial to PrintLab here!